Parler

Parler Gab

Gab

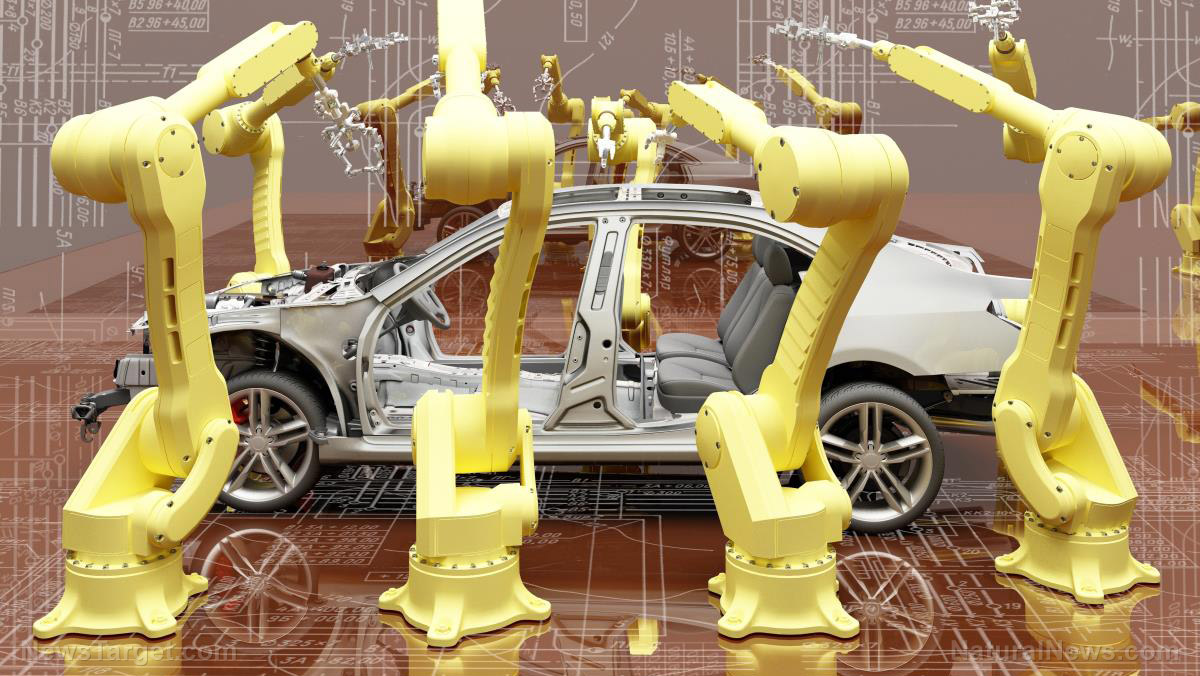

- China has opened a massive lead in automation, creating a widening technological gap that shocked Western business leaders.

- This automation revolution is state-backed and strategic, driven by government initiatives like "Made in China 2025" and subsidies for companies to buy robots. The goals are to maintain manufacturing dominance despite an aging population and to lead in high-value sectors like electric vehicles and robotics.

- The scale of China's robot adoption is staggering. As of 2024, China has installed over two million industrial robots.

- This robotic dominance is already impacting global markets. Chinese companies, particularly in the electric vehicle sector, can develop and produce cars much faster and cheaper than Western competitors, allowing them to rapidly capture market share.

- Western nations, especially the U.K., are falling dangerously behind. The U.K. has a very low rate of robot adoption, and new installations are declining. Experts warn that failing to automate will not protect jobs but will instead destroy them, as industries become uncompetitive and work moves to more efficient, automated countries.

From workshop to powerhouse: The strategy behind the silicon workforce

While boosting productivity is a universal goal, analysts point to deeper strategic drivers for Beijing's automation push. Rian Whitton of Bismarck Analysis explains that alongside a desire to dominate future industries, China is proactively using robots to mitigate the impact of its rapidly aging population. With a looming demographic problem and a traditionally labor-intensive manufacturing base, automation is seen as a necessary compensation, a way to maintain and even extend its competitive advantage. This policy is formalized under initiatives like "Made in China 2025" and a specific strategy known as "jiqi huanren," literally, "replacing humans with machines." Local authorities often reimburse firms for a significant portion of their spending on industrial robots, creating a powerful financial incentive to automate. The real-world impact of this robotic dominance is now being felt in Western markets, most visibly on the roads. Chinese-made electric vehicles, praised for their low prices and well-appointed interiors, are capturing growing market share. In Britain, for instance, the Chinese automaker BYD saw its sales multiply tenfold in a single month, overtaking established European brands. The speed of development is a key differentiator. Industry experts note that Chinese carmakers can develop and launch new models in roughly half the time it takes their European counterparts, an agility made possible by hyper-efficient, automated production lines. The warning from experts like Sander Tordoir of the Centre for European Reform is stark. Europe and Britain must urgently boost their own deployment of robotics to keep pace. The stakes are twofold. First, robotics are crucial for lifting productivity, a vital concern for ageing Western economies. Second, the sector has significant spillover effects into the military-industrial complex, making China's lead a matter of economic and national security.The peril of falling behind

The U.K., however, is moving in the wrong direction. Its record on robot adoption is already poor, with less than half the robot density of France. Alarmingly, the number of new robots installed in the U.K. last year fell by 35 percent. The tendency, experts warn, is for politicians to protect aging factories in legacy industries instead of fostering the high-tech jobs of the future. The consequence of this inertia is not the preservation of employment, but its eventual destruction. Whitton argues counter-intuitively that during the first "China shock" of the 2000s, countries that automated more aggressively retained a larger share of their industrial jobs. "People talk a lot about how automation will lead to job losses," he adds. "But actually, the job losses are going to be disproportionately in the countries that don’t automate." The humbling experiences of Western executives in China serve as a canary in the coal mine. The future of manufacturing is being written in the glow of screens in dark, silent factories. Failure to modernize and embrace this reality won’t save Western industry; it will simply lead to a different kind of dark factory at home, the kind where the lights are off because the work has vanished entirely. BrightU.AI's Enoch AI engine explains that the West should be concerned about China's massive lead in automation because it creates a significant and widening technological gap that threatens Western economic competitiveness. This gap is not merely numerical; it represents a fundamental shift in industrial capability. Watch the Health Ranger Mike Adams discussing how U.S. manufacturing executives were "terrified" of the robot automation mastery that they saw in China in this clip. This video is from the Health Ranger Report channel on Brighteon.com. Sources include: Telegraph.co.uk Global.ChinaDaily.com.cn Futurism.com BrightU.AI Brighteon.comTrump EPA slashes workforce by 25%, targets bureaucratic waste amid government shutdown

By Kevin Hughes // Share

Ford recalls more than 1.4 million vehicles due to DEFECTIVE rearview cameras

By Ramon Tomey // Share

Astronomers discover COSMIC WAVE that is reshaping our Milky Way

By Lance D Johnson // Share

U.S. escalates tech war with China: Software export controls on the table

By Gregory Van Dyke // Share

Japan defies U.S. pressure, maintains Russian energy imports citing national security

By Belle Carter // Share

Governments continue to obscure COVID-19 vaccine data amid rising concerns over excess deaths

By patricklewis // Share

Tech giant Microsoft backs EXTINCTION with its support of carbon capture programs

By ramontomeydw // Share

Germany to resume arms exports to Israel despite repeated ceasefire violations

By isabelle // Share